Updated on: October 15, 2024 7:00 pm GMT

Did you know that the type of motor driving your favorite power tool or electric vehicle can significantly impact performance, efficiency, and maintenance? In the constantly evolving landscape of technology, the debate between brushed and brushless motors is more relevant than ever. This article delves into the fundamental differences, advantages, and applications of both types, providing you with essential insights to make informed decisions when selecting motors for your projects or understanding their usage in everyday devices. Whether you’re a hobbyist, a DIY enthusiast, or a professional, grasping the nuances of brushed versus brushless motors can enhance your knowledge and optimize your choices. Join us as we explore these two motor types, their inner workings, and what they mean for the future of engineering and technology.

Understanding the Fundamental Differences Between Brushed and Brushless Motors

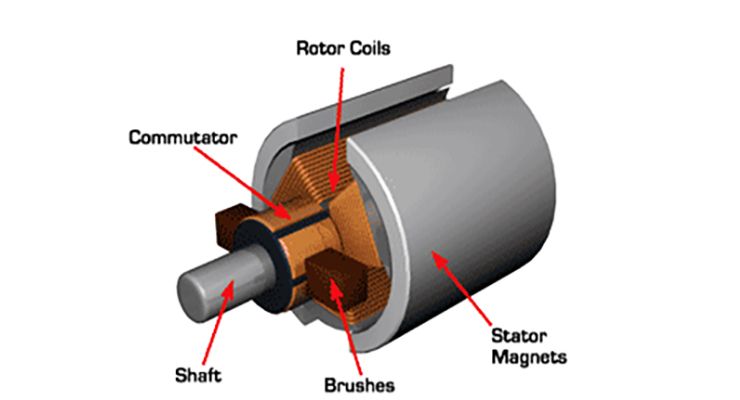

Brushed motors have a simple design that is easy to understand and use. They rely on carbon brushes that make contact with the motor’s commutator. This helps the motor spin but can also cause wear and tear over time. Brushed motors are good for low-cost applications and are often found in toys or small devices. However, they can create sparks and produce more heat, which may lower their lifespan. Common uses include power tools and household appliances due to their straightforward operation.

On the other hand, brushless motors use electronic controllers instead of brushes. This means there’s less friction and no sparking, leading to a smoother operation. They are often more efficient and can provide higher power output while consuming less energy. Brushless motors tend to last longer than their brushed counterparts. They’re widely used in applications that require precision, like drones and electric vehicles. Advantages include quieter operation and less maintenance due to the lack of brushes.

Evaluating Performance Efficiency and Lifespan in Motor Selection

When choosing between brushed and brushless motors, it’s crucial to consider their performance efficiency. Brushless motors generally offer superior efficiency due to their design. They use electronic commutation instead of physical brushes, resulting in less friction and energy loss. This means they convert more electrical energy into mechanical energy, typically achieving efficiencies above 85%. In contrast, brushed motors often operate at around 75% efficiency. This difference can significantly impact the duration of operation, especially in battery-powered devices.

Lifespan is another important factor. Brushless motors are built to last longer than their brushed counterparts. They can run for 10,000 to 30,000 hours of operation, while brushed motors may only last for 1,500 to 7,000 hours before wearing out. This durability stems from the absence of brushes, which wear down over time. Choosing a motor with a longer lifespan can save you money on replacements and maintenance, making brushless motors a wise investment for long-term projects.

Guidelines for Choosing the Right Motor Type for Your Application

When selecting a motor, first consider the power needs of your application. If you need high torque at low speeds, a brushed motor might be best. They are simpler and cheaper but can wear out quickly. For applications requiring higher speeds and efficiency, go with a brushless motor. Brushless motors last longer and need less maintenance, making them ideal for tasks that demand reliability.

Next, look at the environment where the motor will work. If it’s in a dusty or wet place, a brushless motor offers better protection. Also, think about your budget. Brushed motors have a lower upfront cost, while brushless motors save money in the long run with less maintenance. Keep these points in mind to find the perfect fit for your needs.

Frequently Asked Questions (FAQ)

Q&A Section: Brushed vs. Brushless Motors

Q1: What is the primary difference between brushed and brushless motors?

A1: The primary difference lies in their construction and operation. Brushed motors use brushes to conduct electricity to the rotating armature, whereas brushless motors utilize electronic controllers to eliminate the need for brushes, resulting in reduced friction and improved efficiency.

Q2: What are the advantages of brushed motors?

A2: Brushed motors are generally simpler in design, easier to control, and more cost-effective. They provide higher torque at low speeds and are widely available, making them suitable for various applications, including toys and household appliances.

Q3: What benefits do brushless motors offer?

A3: Brushless motors typically provide greater efficiency, longer lifespan, and reduced maintenance due to the absence of brushes. They generate less heat, have higher torque-to-weight ratios, and are often quieter in operation, making them ideal for applications like drones and electric vehicles.

Q4: How does maintenance differ between brushed and brushless motors?

A4: Brushed motors require regular maintenance, including brush replacement and cleaning of commutators due to wear over time. In contrast, brushless motors require minimal maintenance since they do not have brushes to wear out, significantly increasing their service life.

Q5: In what applications are brushed motors commonly used?

A5: Brushed motors are commonly used in applications where cost is a critical factor, such as small appliances, electric toys, and automotive accessories. Their simple control systems make them easy to implement in basic applications.

Q6: Where are brushless motors typically preferred?

A6: Brushless motors are preferred in high-performance applications requiring efficiency and precision, including electric vehicles, computer cooling fans, and industrial machinery. They are also increasingly common in portable power tools and drones, where battery life and performance are essential.

Q7: Do brushed or brushless motors offer better torque?

A7: Brushed motors generally provide better torque at low speeds, making them suitable for applications that require immediate starting torque. However, brushless motors can outperform brushed motors in torque delivery across a wider range of speeds due to their advanced control systems.

Q8: Which motor type is more energy-efficient?

A8: Brushless motors are typically more energy-efficient because they produce less heat and utilize energy more effectively. This efficiency leads to longer battery life in applications like electric vehicles and portable tools, making them a more economical choice in the long run.

Q9: Can I replace a brushed motor with a brushless motor in existing applications?

A9: In many cases, you cannot directly replace a brushed motor with a brushless motor due to differences in control systems, power requirements, and mounting configurations. Any replacement should consider these factors, and potentially necessitate changes to the controller or power supply.

Q10: How do I choose between brushed and brushless motors for my project?

A10: The choice between brushed and brushless motors depends on your specific application requirements. Consider factors such as cost, efficiency, maintenance needs, size, weight, and performance requirements. If low cost and simplicity are paramount, a brushed motor may suffice. For higher efficiency and longer life, opt for a brushless motor.

The Conclusion

the comparison between brushed and brushless motors reveals key distinctions that can significantly impact performance, efficiency, and longevity. Brushed motors, with their simpler design and lower cost, often appeal to budget-conscious consumers and applications requiring straightforward functionality. In contrast, brushless motors offer superior efficiency, reduced wear, and enhanced control, making them the preferred choice for high-performance applications.

Understanding these differences is crucial for anyone involved in selecting the appropriate motor type for specific needs. As technology continues to evolve, the relevance of each motor type will depend on advancements that address their inherent strengths and weaknesses. For those interested in making an informed decision, it is advisable to consider factors such as application requirements, cost, and desired performance characteristics.

Motor technology is always changing and getting better. By keeping up with the newest trends and ideas, you can make smarter choices. We invite you to learn more about motor technology, look at different resources, and think about how the information in this article can help you with your own projects or ideas.